Since I actually did build the thing about a year ago, I’ll post my thoughts about the construction sequence, and especially about the instructions and some peculiarities of the kit.

There are 23 construction steps and though they are logical I built my example in a bit different way. Also, I noted some errors I am discussing below.

Step 1: wheels – lots of them. Assembling the front wheels is no problem. The drive sprockets are handed (different) on the actual machine, but not in the kit. Dragon has issued you with 2 identical assemblies.

I had to remove the locating pins on the double roadwheels to have them fit as on the real deal.

In Step 2 you will be dealing with the front suspension, which is nicely detailed, except for the lack of a connection to the steering mechanism.

Torsion bars and the final drive covers – simple and hassle-free.

At the aft end of the hull instructions tell you to glue two plates marked B41 and B42. That, however, is wrong. Parts are actually black A41 and black A42.

N.B. The idler arms (parts B22 and B23) have to point almost vertically upwards, so that the number of track links in each run is as in the instructions – don’t glue them yet 🙂

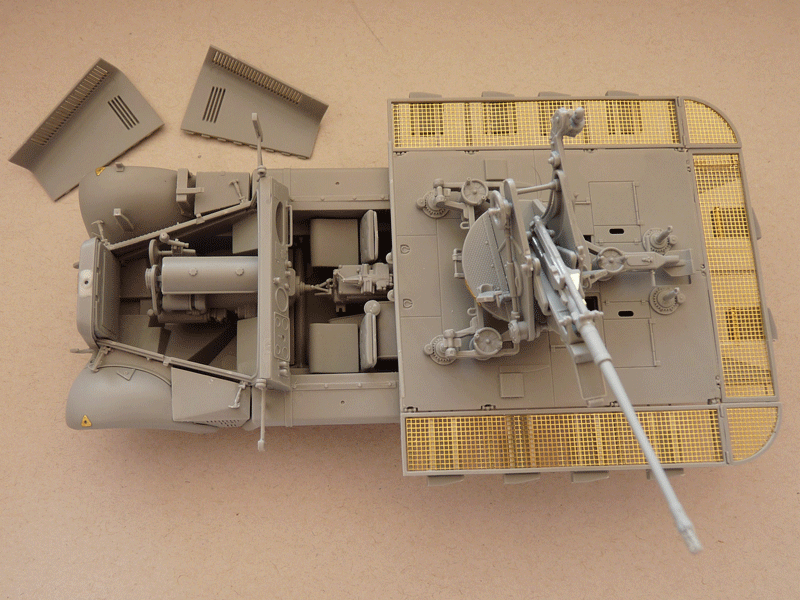

Step 3 (engine). The fit of two halves of the engine block is not what you’d expect from such a kit. The additional details you glue will not hide the seams, so if you are having the bonnet open – work on the filling and sanding.

The complete engine must be able to fit in the engine compartment and stand upright by itself. If it doesn’t – you’re in trouble. Don’t glue part B47 before you’re done with the whole engine – its position makes it very easy to break.

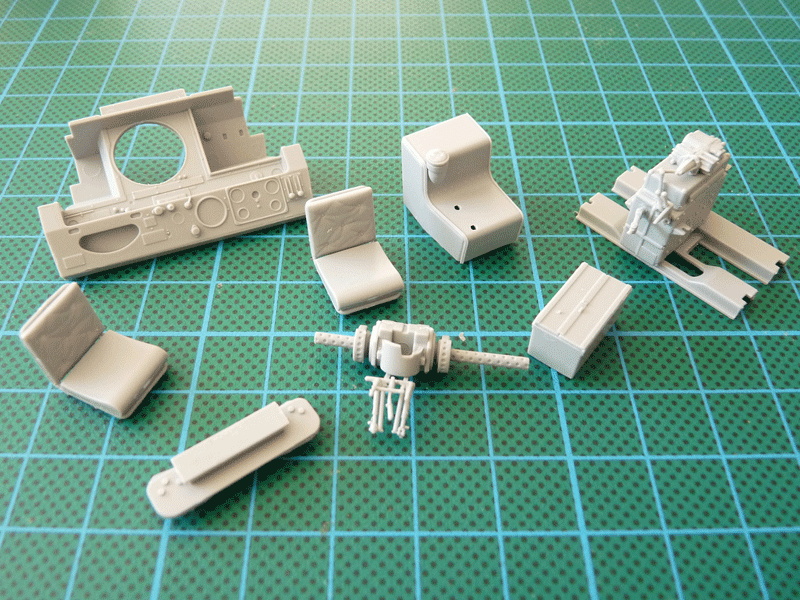

Step 4 (transmission). Lots of tiny and thin parts that require careful cleanup. Do test fit, because a lot of the pieces meet at odd angles and still need to connect to each other. Consult your references about the position of part B10 against both the gear box and the final drives on the side, as there are no locating pins or other aids. Part B6 is the driveshaft connecting the engine and the transmission – it goes between the seats. Both parts B2. will also benefit from some careful positioning.

Step 5 (driver and commander’s seats). Paint components (frames and cushions) separately and join them when finished weathering. This will enhance their appearance in the open-topped driving compartment.

Step 6 – mounting the transmission subassembly together with the fuel tank and a toolbox (two options available) to a single frame that is set behind the seats.

Step 7 – engine bulkhead and instrument panel. I did dry-fit the bulkhead (part A40) to the hull and the dash parts. Decalling instructions for the dashboard is provided in this step. Adding the rest of the parts will make the process very hard to perform at a later stage, so follow the instructions (just this once) and it will be OK.

As the tachometer face is recessed rather deeply, I punched a clear disc of the same diameter and glued it with a drop of clear acrylic gloss. I used drops of white glue over the rest of the dials to add a sense of depth to them.

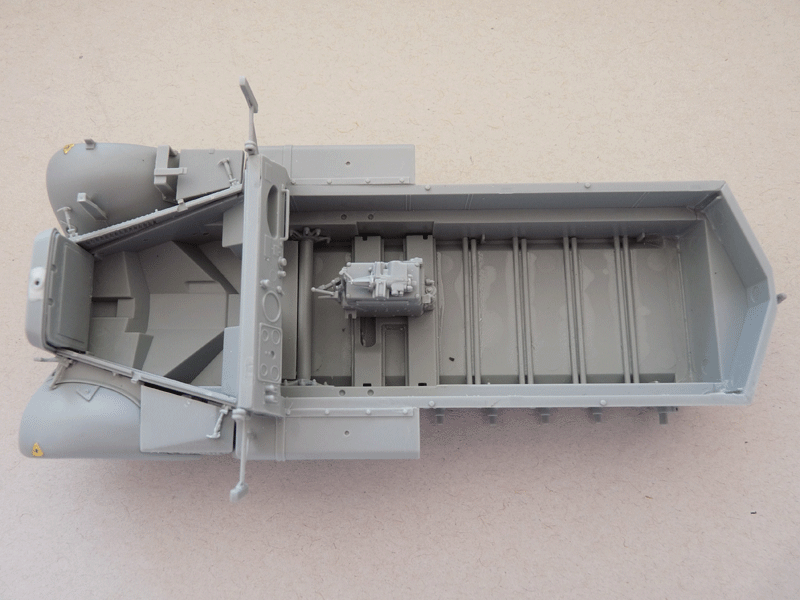

Step 8 – getting all the pieces so far together. If you’ve read through so far this stage should pose no problem. The parts coded MA6 are not in the kit at all. According to the part plan in my kit the only part MA6 is the manufacturer nameplate at the top of the radiator housing (clearly reading DEMAG).

I myself left the wheels off for later to ease hull weathering.

Step 9 – setting the engine, radiator and supporting bars, fan ducting (but no fan ti fit in it :-D), front bumper and number plate in place.

When mounting part A31 please note that the rear lock hinge is not molded on it – you need to add part A85. Also, the radiator cover is shown without the filler receptacle (which is molded on the actual part) and is missing any instructions about adding the filler cap (part A17). In my example there is a molding recess around the opening that needs to be puttied away.

To make alignment of the fenders easier you could also add part A39 to the left one at this time, fix it into position, and then adjust the left fender accordingly.

Steps 10 and 11 – rear fenders, boxes, windshield, tool complement and various other attachments.

NB. Dragon includes the full-length fenders for the standard SdKfz 10 tractor in the kit. The parts you will use are blue D15 and blue D16. Consult your references for proper vertical positioning and fill the holes on the upper surfaces.

To avid breaking off the clear parts please don’t attach the windshield at this time. It is secured in position by two hinges you add in this step – parts A74 and A75 – so if you glue them now you will need to remove one of the locating pins of the windshield to be able to mount it later.

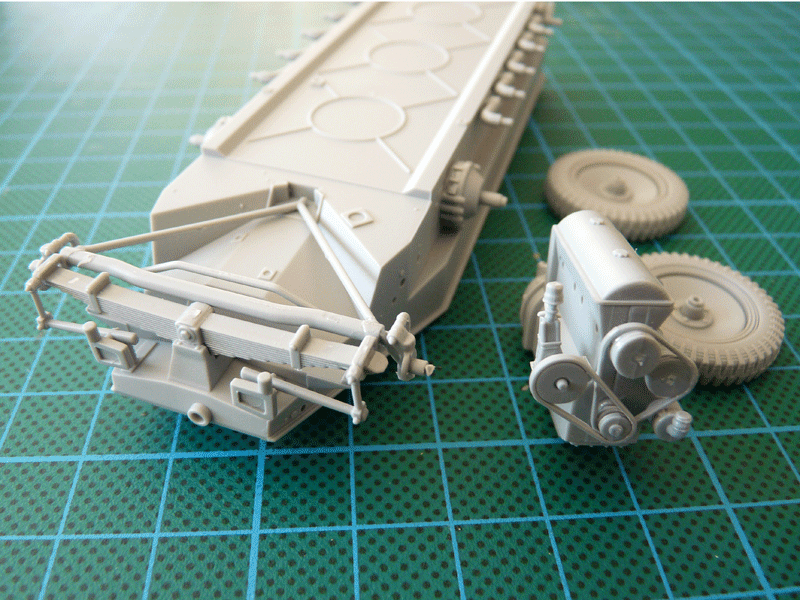

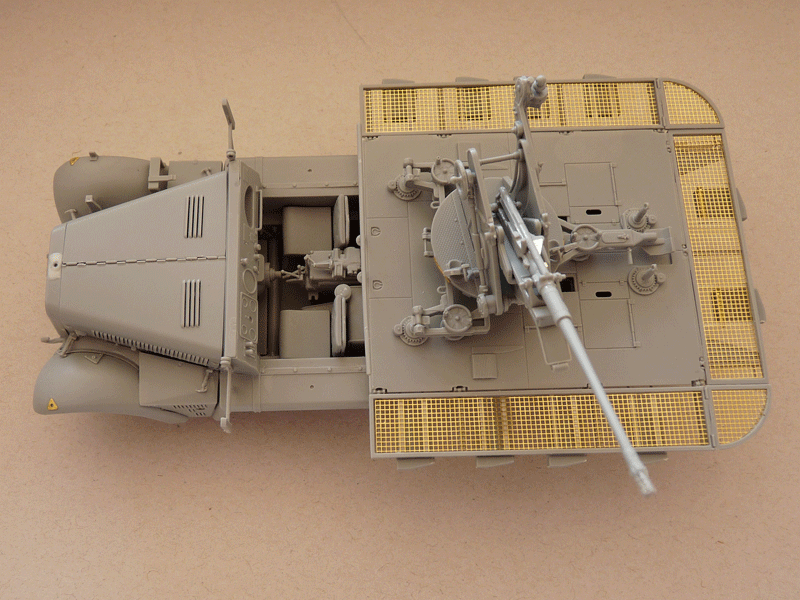

Step 12 – main gun platform. This step deals with the platform support frame and the gun securing posts.

Part blue D11 is the support frame – dry-fit it with the hull tub to see which parts will actually be visible – you will save yourself a lot of work.

Leave parts blue D12 (on the front supports) until you mount the gun itself – these two lock the gun in place.

There is another pair of parts blue D12 to the drop-board locks. However, these details are actually molded within parts blue D4 rather than as as separate pieces.

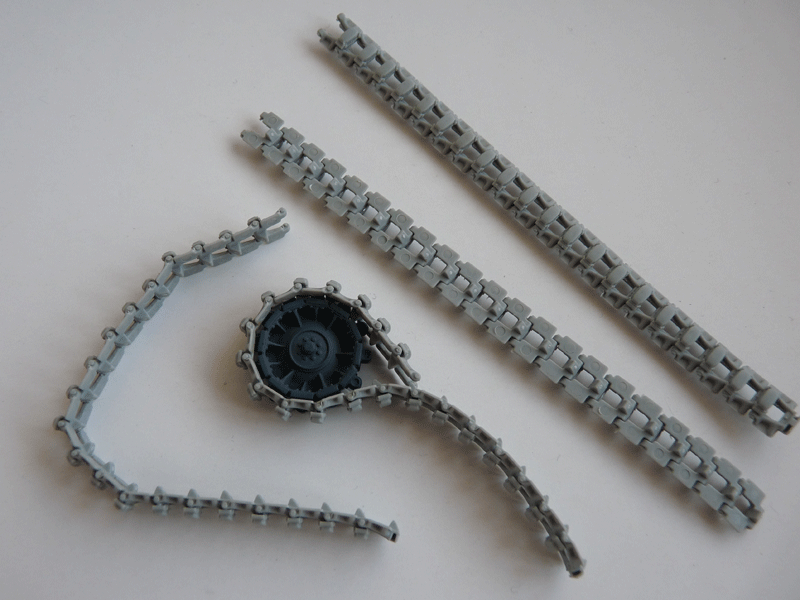

Step 13 – assembling track runs is rather easy. Rather than swamping the tiny parts with modelling glue, add just enough to secure the rubber pads (part N1) in place. This will keep the tracks flexible and will make adding them around the wheels easier.

My advice:

– leave the drive sprockets off, insert the idler arms in their positions, but don’t glue them;

– build each of the track runs (42 links in each) without joining their ends;

– glue each sprocket about the middle of the respective track run, then fix it in its position on the hull;

– adjust the track runs over the roadwheels and around the idlers, and then join the two ends of each track run;

– adjust the idler position so you get the right amount of tension on the track as per reference images. Fix the idler arm with glue.

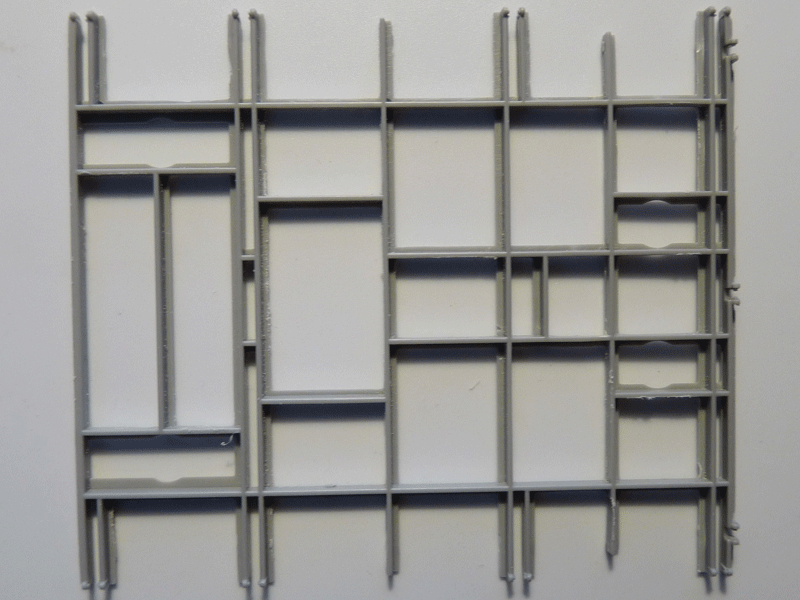

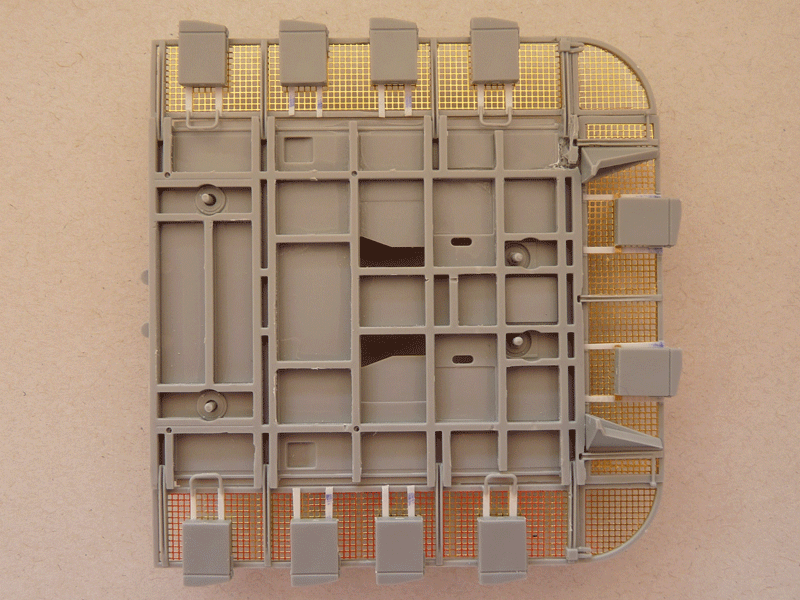

Step 14 – gun crew seats and gun platform flaps.

The PE mesh screens for the left and right platform boards are drop fit. Part MA25 (the screen for the rear board), is 4 rows too long and needs to be shortened with a sharp blade. Parts MB2 – the strips you mount the ammo boxes (parts Z1) on – were too short in my example. I used plastic strips instead.

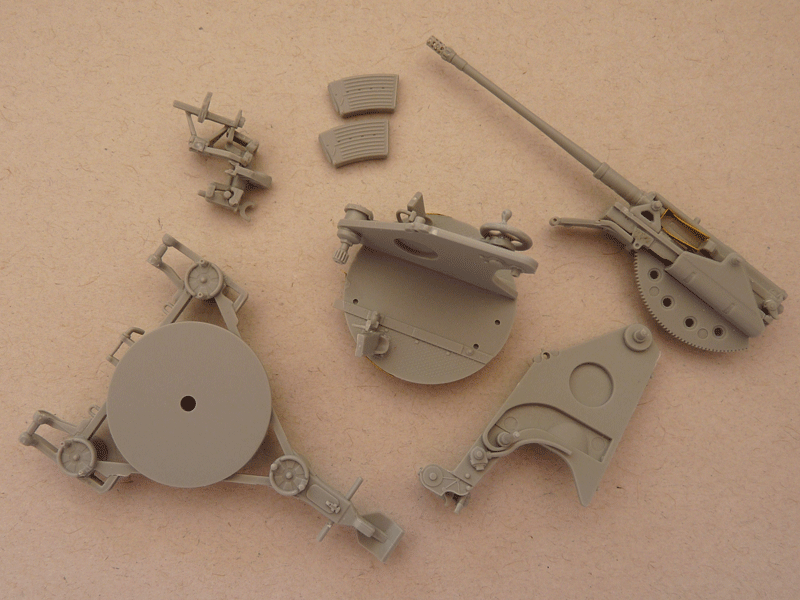

Step 15 – gun turntable. I’ve noted the following errors in the instructions:

– parts MC3 are actually MB1;

– parts MC2 are MB2 in the kit;

– positions for parts A65 and A70 are swapped in the instructions (the correct part is shown with the number of the mirror part).

Step 16 – gun sight. Two options here, pick the one to your preference (or reference).

Step 17 – assembling the gun cradle and barrel. Another error – part black A10 should be blue A10. Some sanding might be required for parts blue A10 and A31 to fit properly; same for blue A14 and blue A48.

Step 18 – assembling the gun. Lots of tricky assembly here due to the many interconnected parts. You will need to select the elevation angle of the gun at this stage, as the barrel/cradle assembly connects to the gun sight via a lever on the left – you will notice the axle on that side is longer the gun barrel and line of sight of the gun need to be parallel.

I’ve drilled the holes in the flame-damper using a 0,6 drill bit.

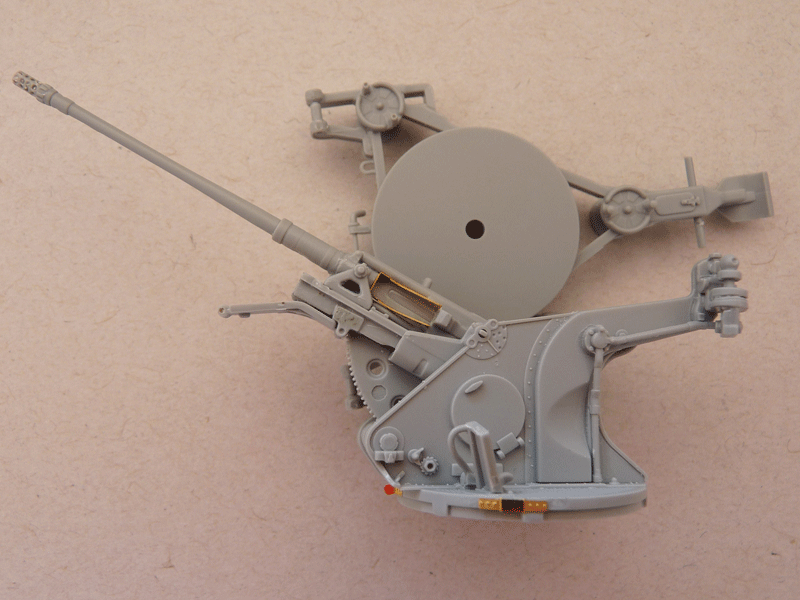

Step 19 – gluing the gun to the base and three more parts.

Step 20 – adding the horizontal traverse wheel and gunner’s seat. I glue pieces of paper towel to the seat and backrest using white glue to simulate texture.

Step 21 – what you do in this step depends on the elevation angle you’ve selected for the gun in step 18. Two options – locked for transport, or in use. Frankly the parts’ optional positioning could be suggested earlier, as the images in step 20 already shows part A58 as fixed in the firing position.

Step 22 – gun shield. What you have to do is bend and glue a heap of 2D to create a complex 3D assembly. There is little reference in the instructions about the position of most of the parts (over 30 plates and a number of PE boltheats and plastic wingnuts), or how the entire shield assembly fits to the gun itself.

I couldn’t get the wingnuts to sit vertically, so the construction went on without them.

Step 23 – mounting gun shields and the gun itself. There are no markings on the plastic parts to suggest the position of neither gun shield, so it’s up to you to find the proper reference (or leave the shield off).

Fixing the entire gun on the vehicle’s cargo platform is a simple task if you read through the instructions and did not glue parts blue D12 on the retaining posts (parts blue D7) as suggested in step 12.

There are several simple self-made additions to the kit to simulate missing details – e.g. the steering column, a connection between the exhaust collector and the the muffler, a hose between the engine block and the radiator, etc.