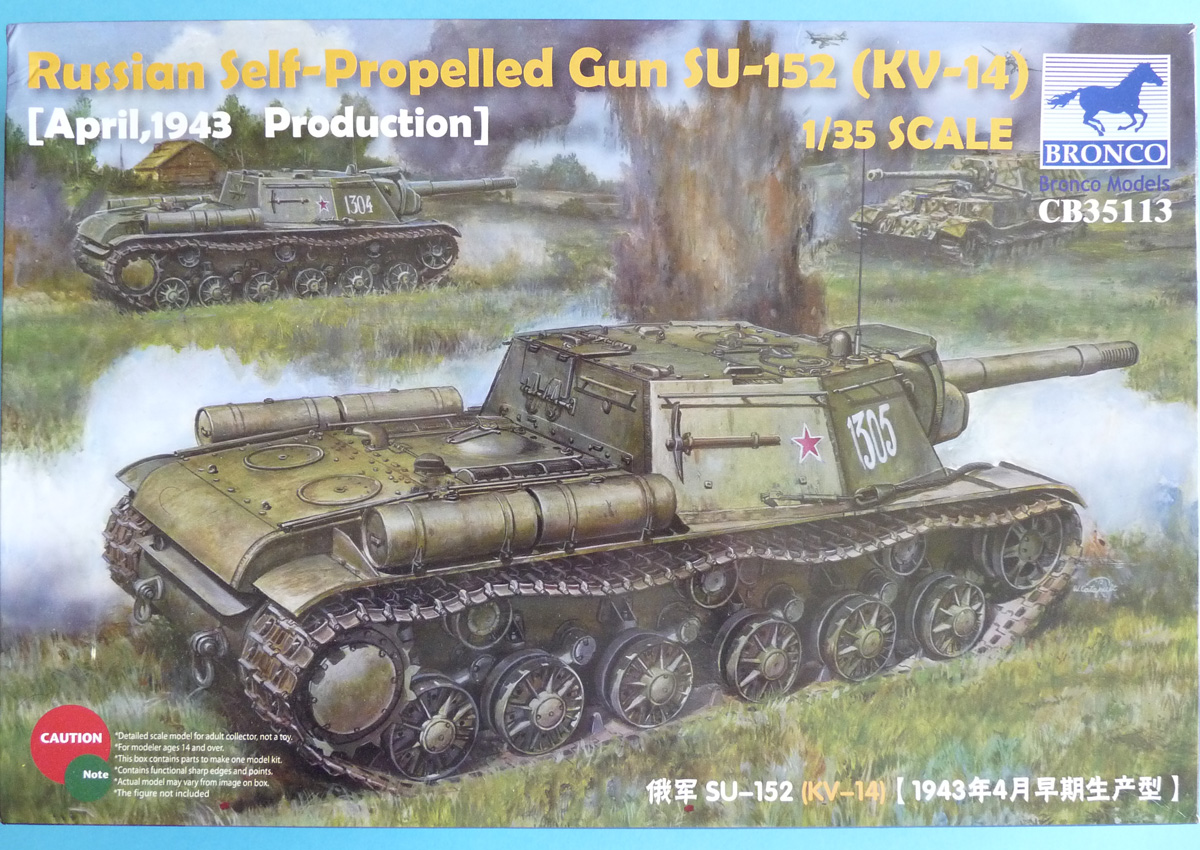

Bronco has released two versions of the legendary Zveroboi SPG (popular nickname for the SU-152): early (the subject of this review) and late production. Confusingly the kit of the late variety appeared first, and this kit was released a few months later – in the beginning of 2013.

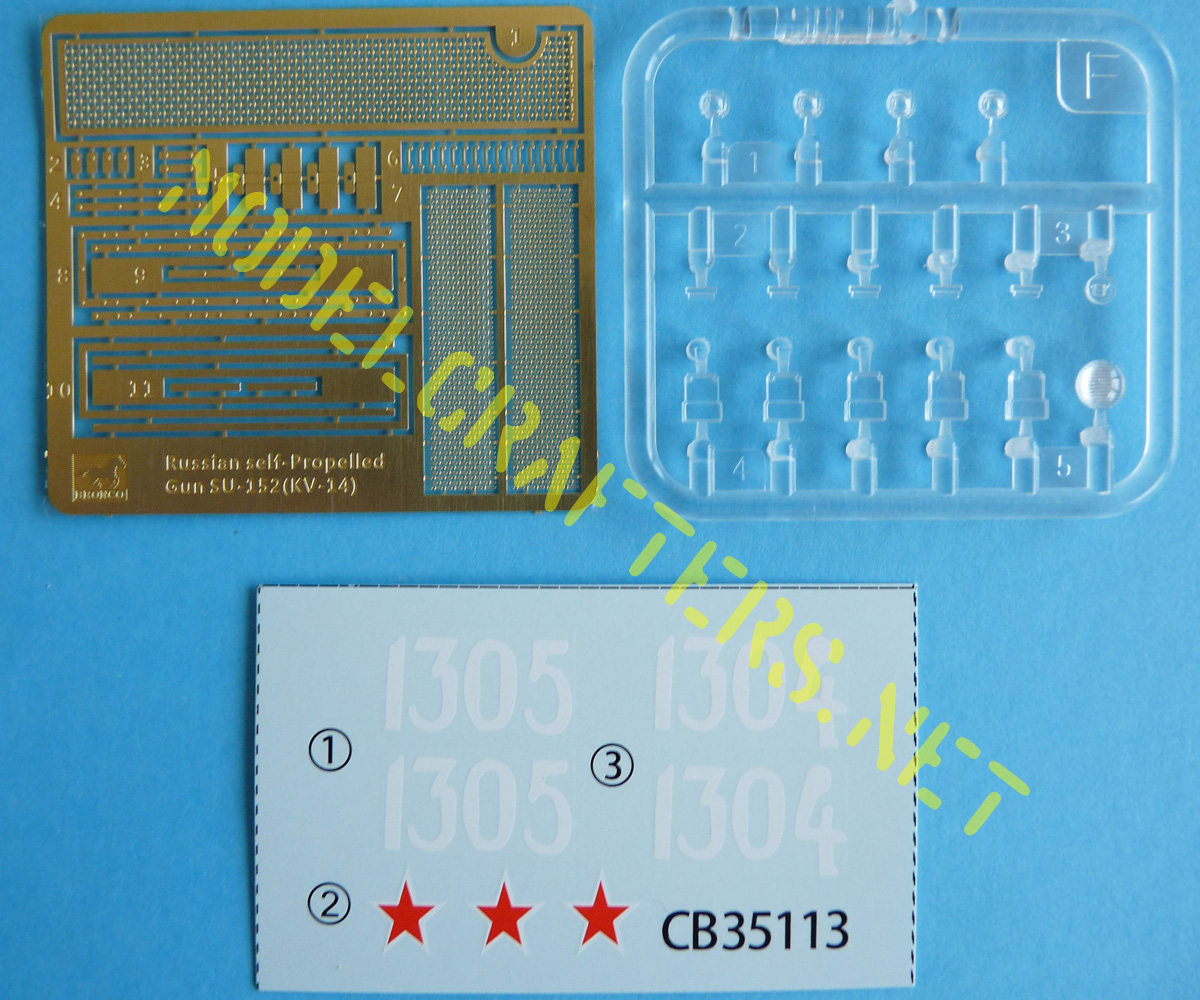

The sprue count alone is staggering: there are 59 sprues, including 1 with clear parts and the hull tub. A PE fret, decal sheet and two lengths of braided copper wire complete the kit.

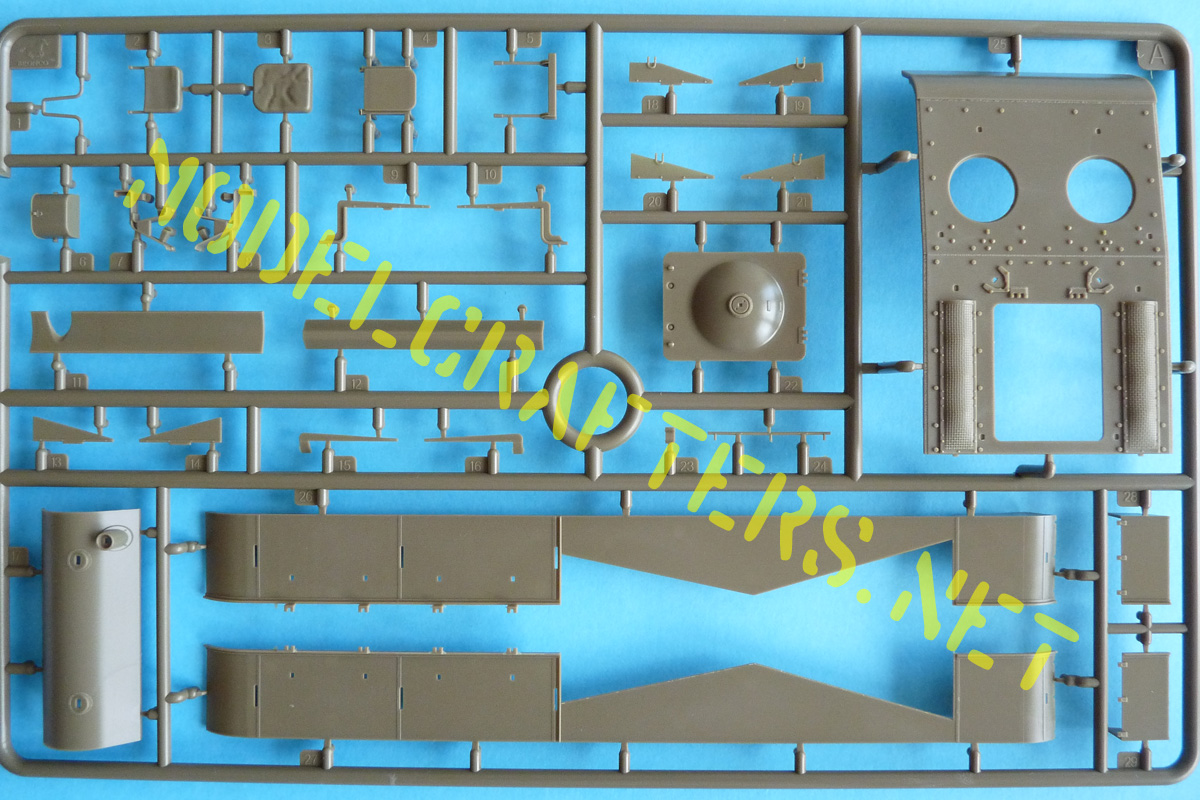

Sprue A contains parts that are applicable to the entire KV-1 line and derivatives. Fenders and engine deck are marked “Not for use” in the parts plan.

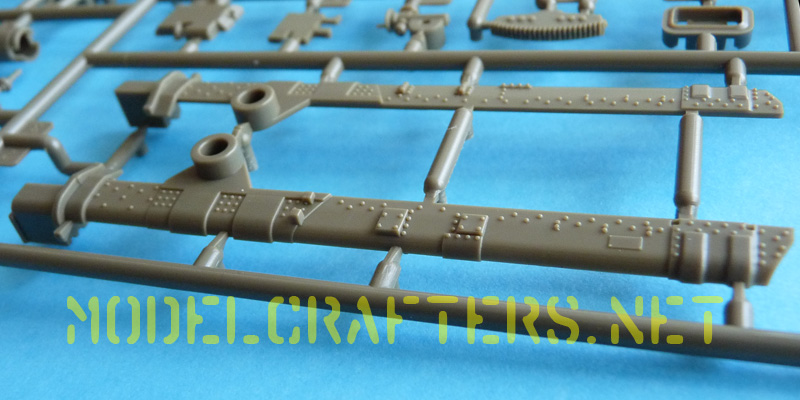

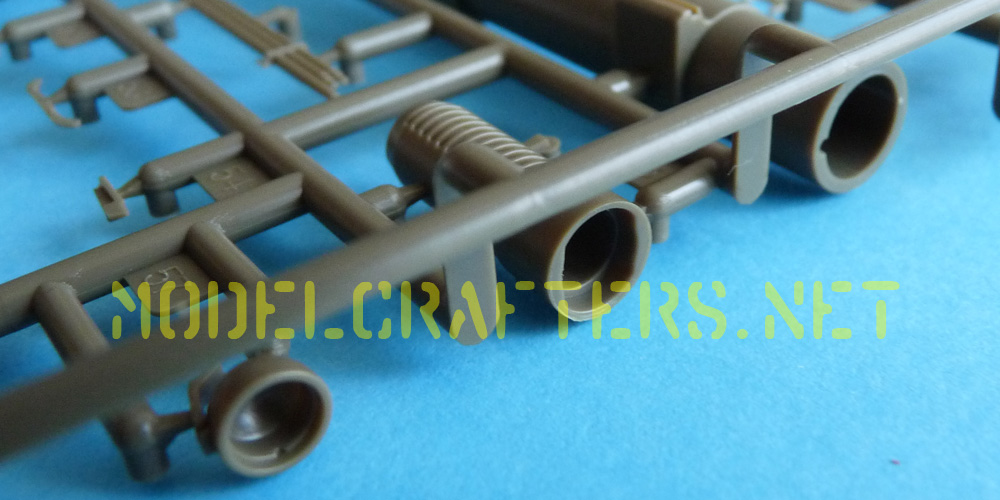

Sprue B caters for the main gun, and let me tell you casting on the ML-20S is some of the best I’ve seen to date.

Note the single-piece barrel and a separate one-piece muzzle brake.

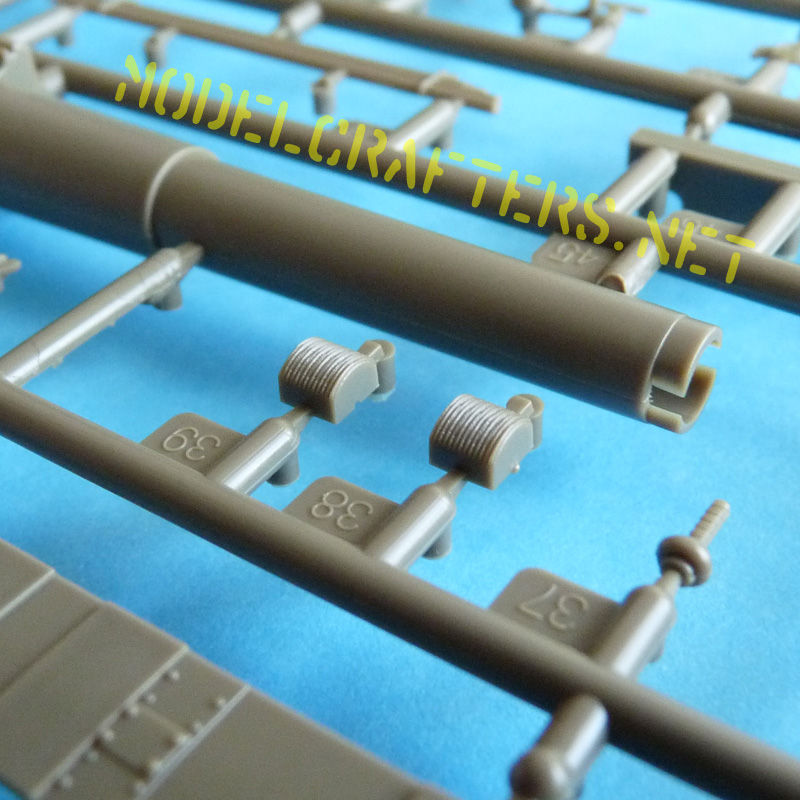

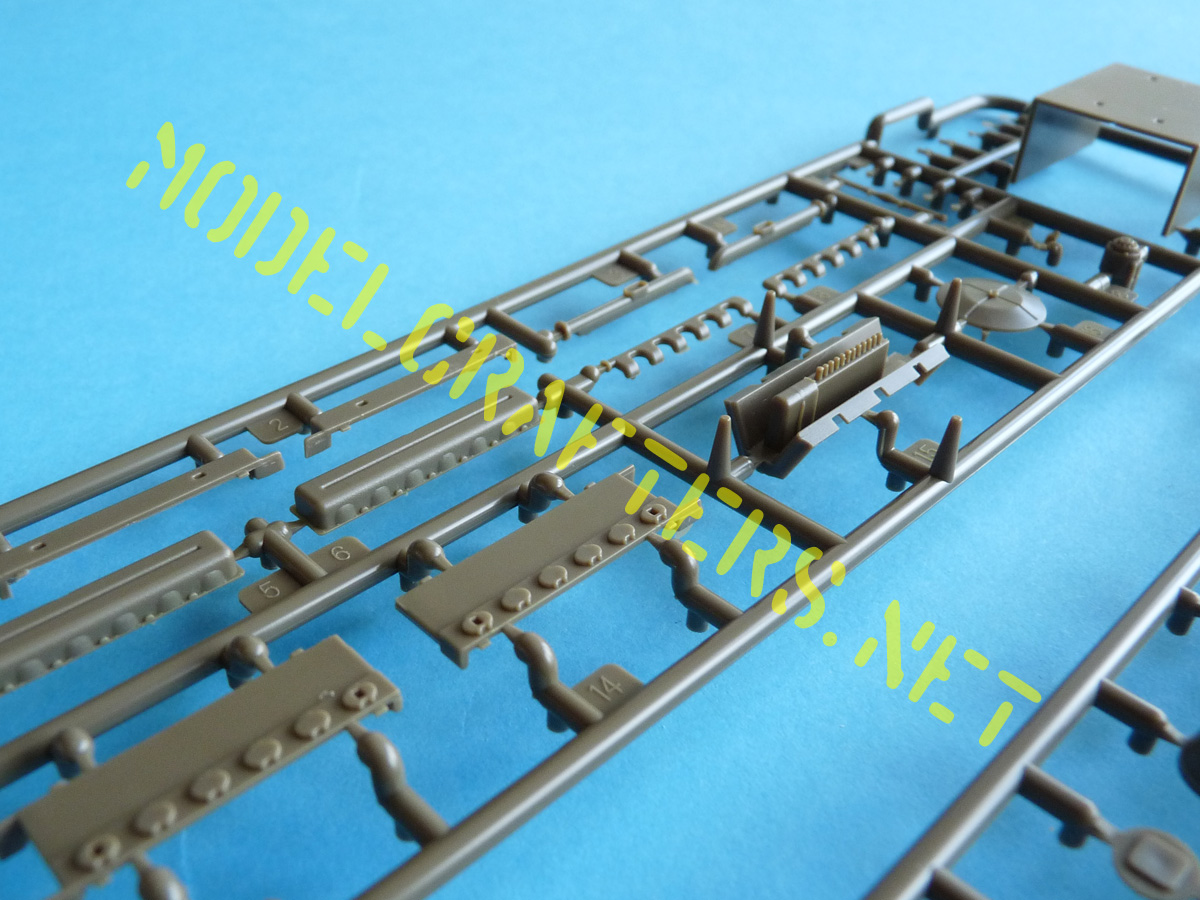

These are parts of the elevation mechanism.

The gear below locks into the teethed rake in the previous picture and actually moves if you elevate or depress the gun.

The two side panels of the gun cradle, studded with rivets just like the real deal.

The barrel and the two halves of the breech; the part on the lower right is the antenna base, which sits atop the casemate.

Some magnificent casting right there – slide-molded single piece muzzle brake.

The rear ends of the gun tube and muzzle brake, and the business end of the headlamp.

Parts for the traversing/elevating frame and mechanism.

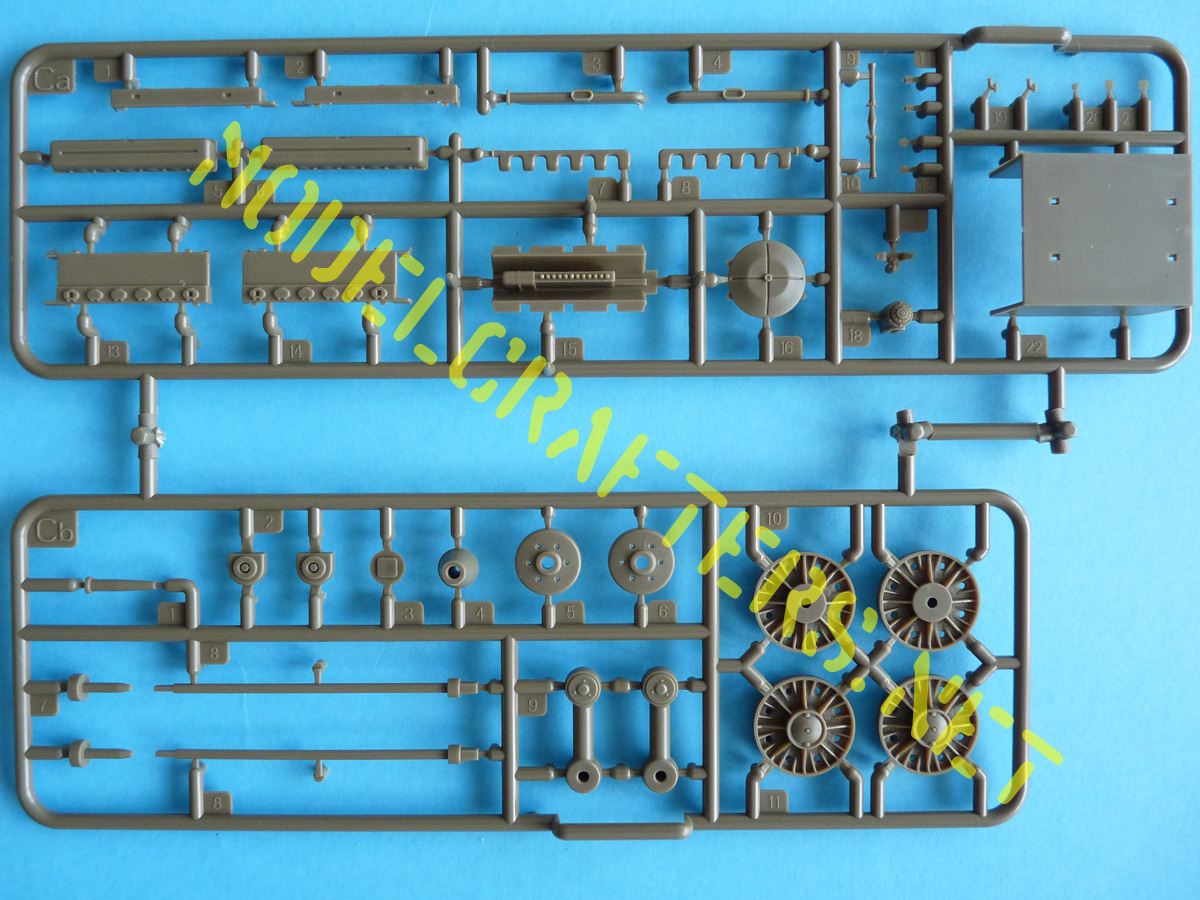

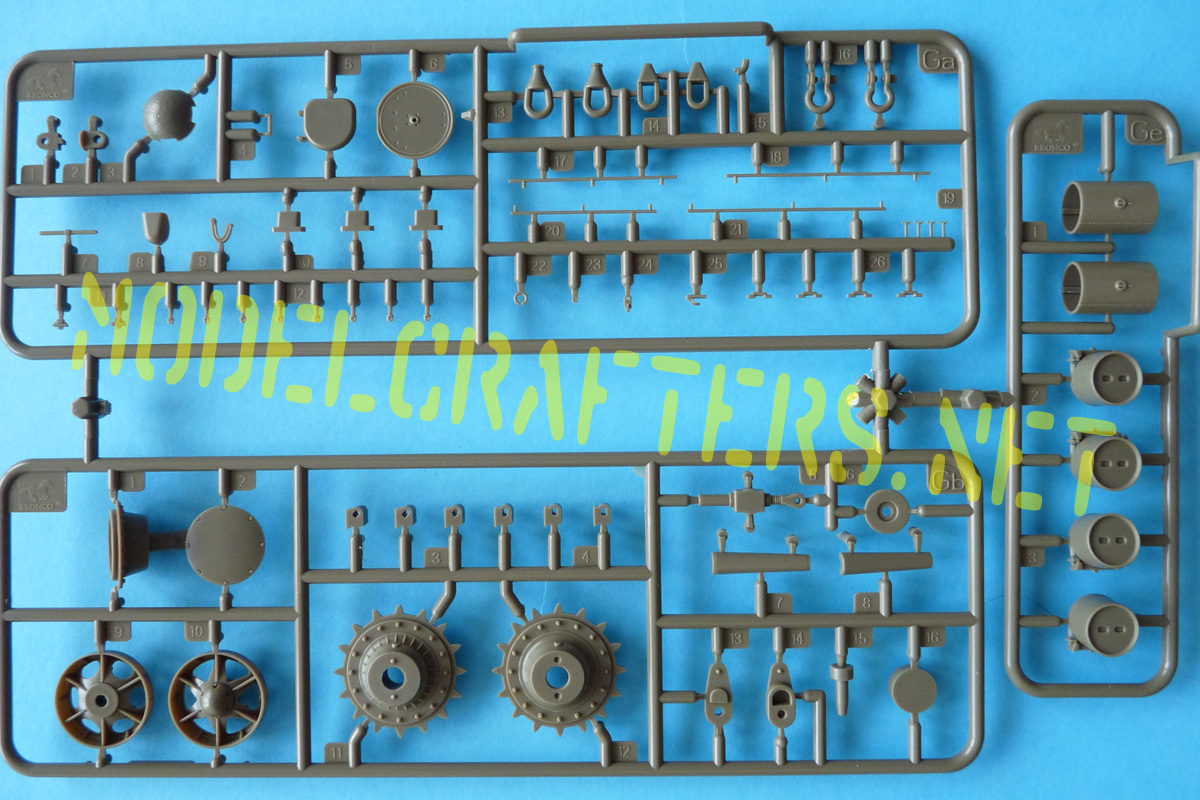

Engine bay parts (sprue Ca). Sprue Cb is one of six providing suspension and return roller parts.

This is the V-2K 12-cylinder diesel. No transmission is provided.

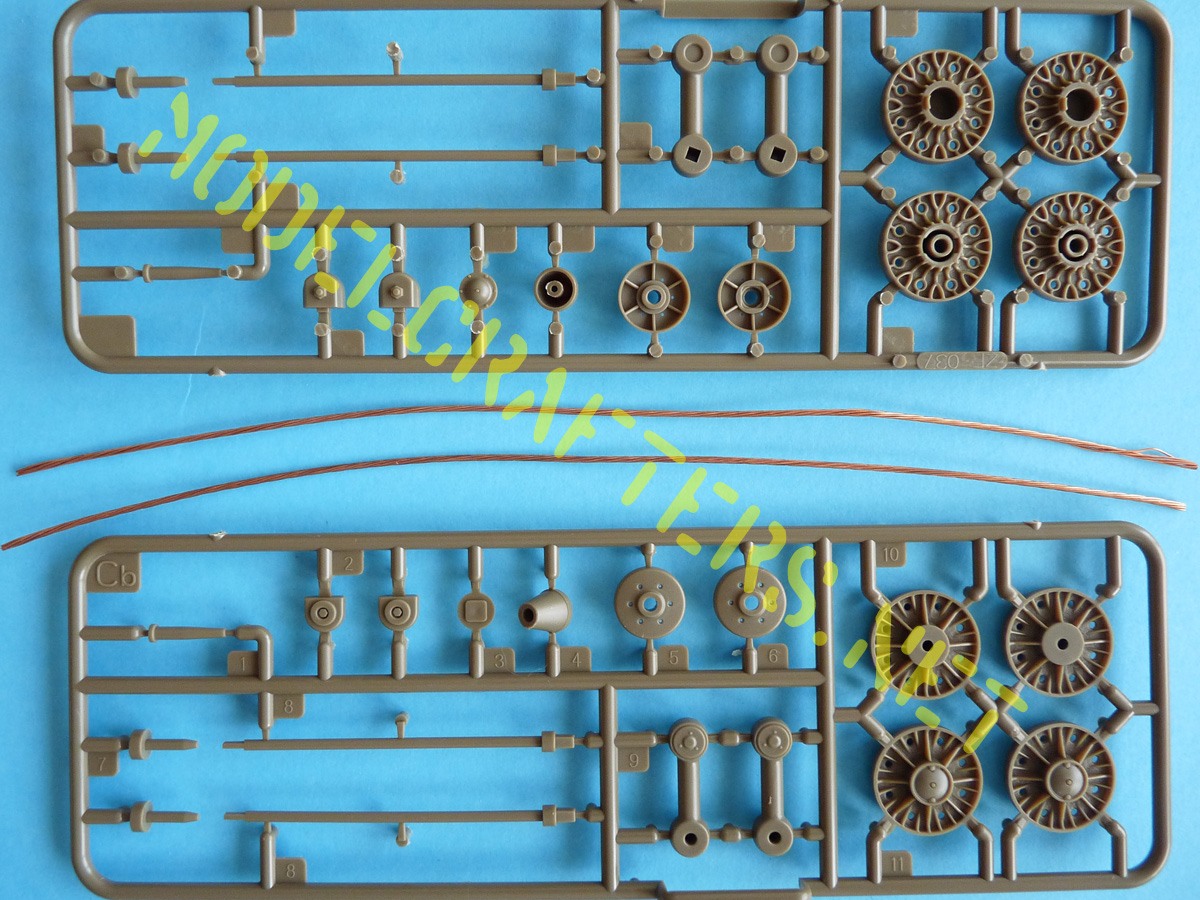

Cb sprues again (both sides) plus a view of the copper cable. You’d need to prime these in order to get the paint to sit right there…

Roadwheels with some excellent details and cast texture around the wheelhub.

Next come the inner faces of either half, and who would’ve thought he’d find such a maze in there 🙂

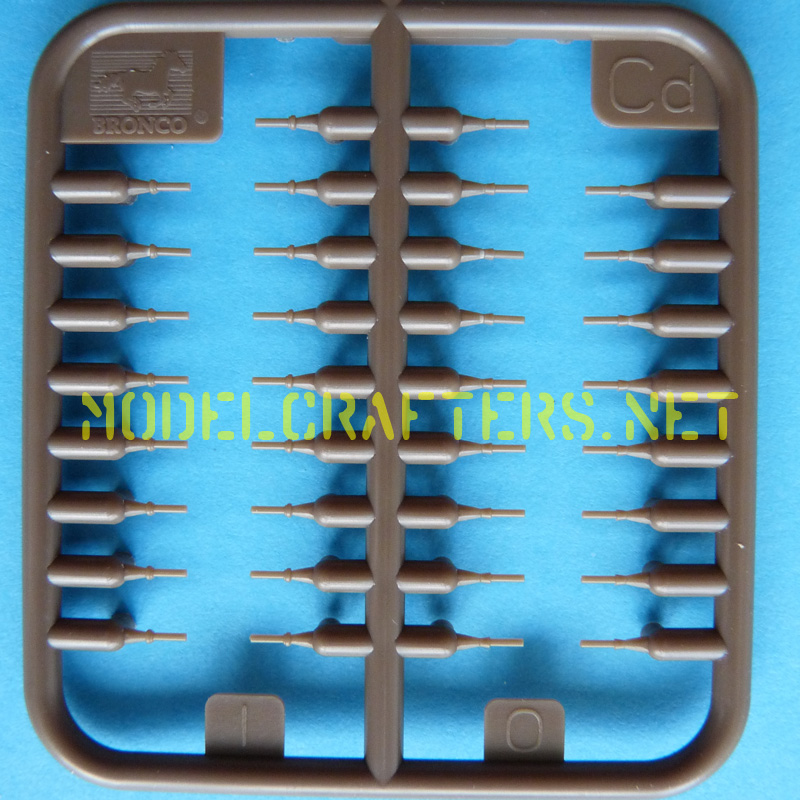

13 copies of sprue Cd hold the track pins. There are two types present – on at each half of the sprue.

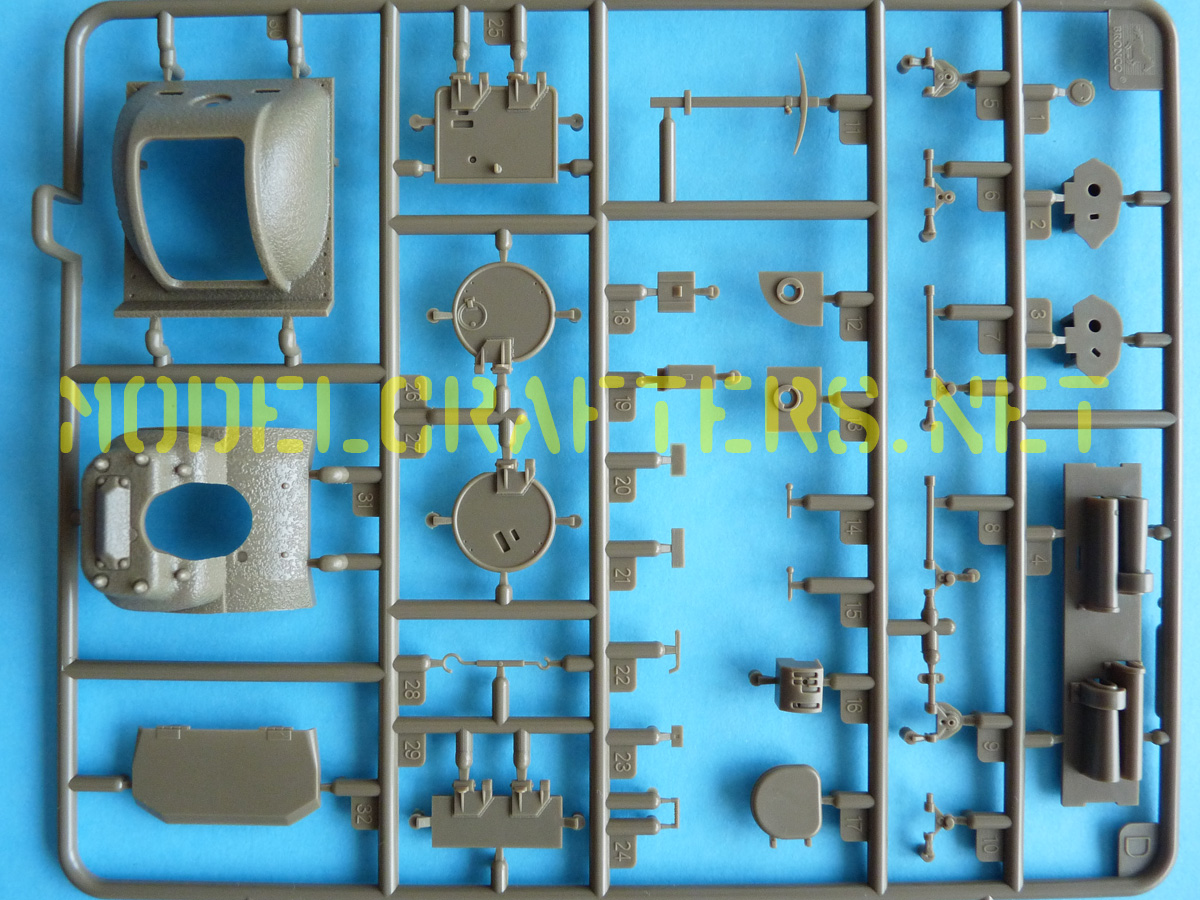

Sprue D holds various details for the superstructure and some rudimentary interior details.

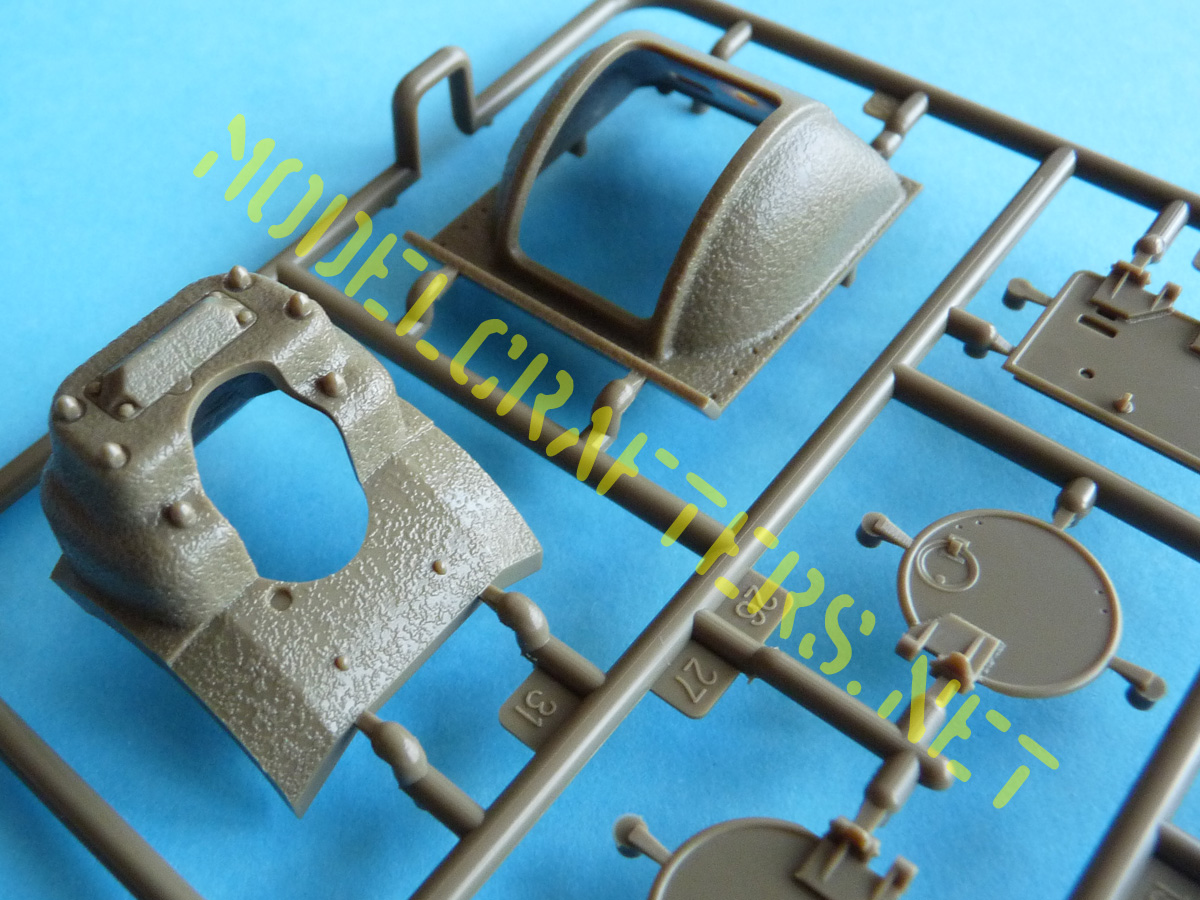

Most notable are (of course) the details for the gun mask, both the fixed “collar” and the mantlet that moves together with the gun. Lovely cast texture there.

You’ve also noticed the hatches – which can all be posed open, closed, or be left moveable – have details on either side to help the vision of the complete model.

The fenders used in the build are on the Eb sprue. Also visible are the new suspension arms and the ends for the external fuel tanks (kit contains both the early and late varieties).

Clear parts, decals, and PE mesh screens. There are parts for the hot air outlet at the back of the KV-1S chassis the SU-152 is built upon, and the intake screens. The latter are made into a multilayer construction that also has to be bent around an injected plastic frame with 3 support ribs.

A look inside the external tanks.

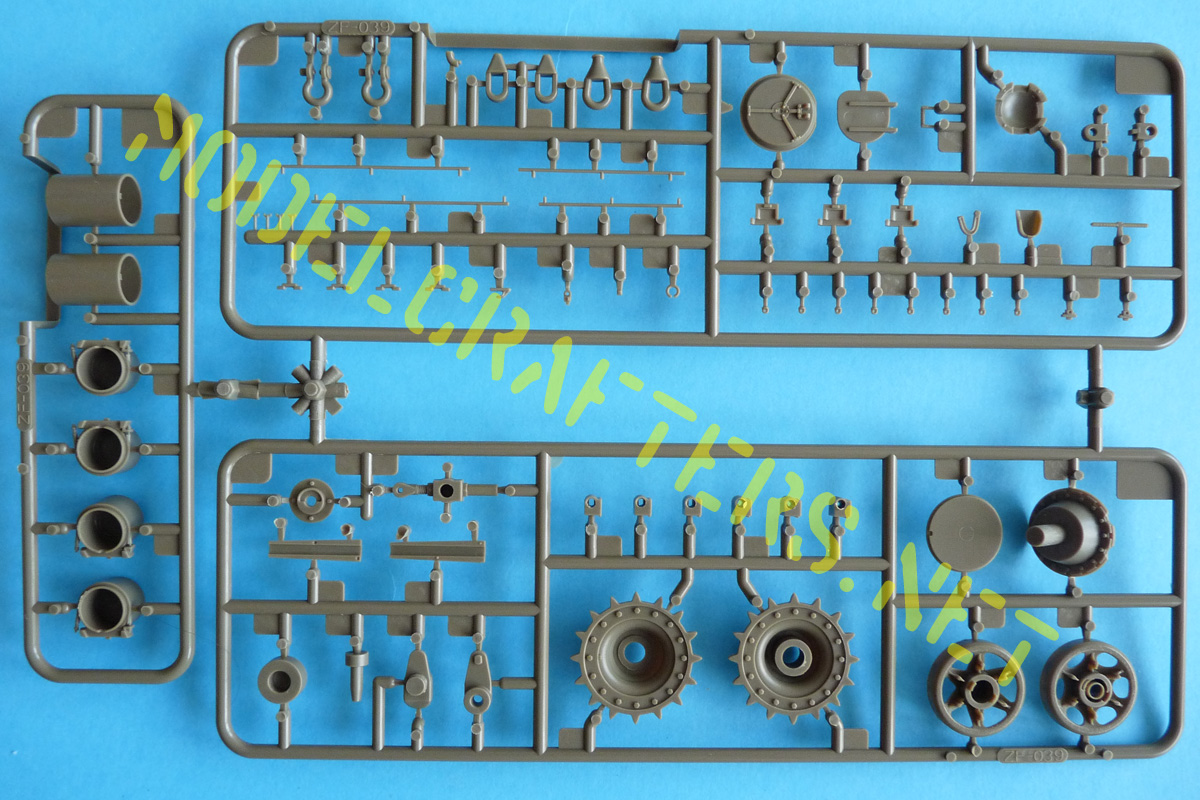

More fuel drums, sprockets, idlers various tow eyelets (2 types), handles, etc.

Other side of the same sprue group. Note lock detail on the inside of the circular transmission access hatch.

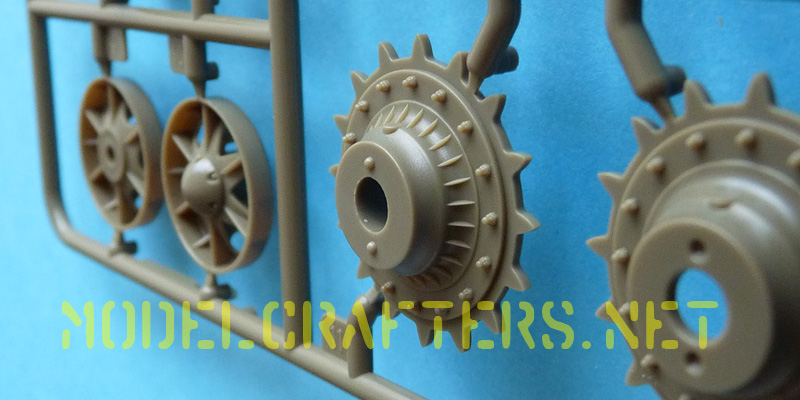

The boltheads and ribs on the inside of the drive sprocket.

Idlers – clever part design so you don’t fumble it…

Closer look on tow cable ends and circular hatch.

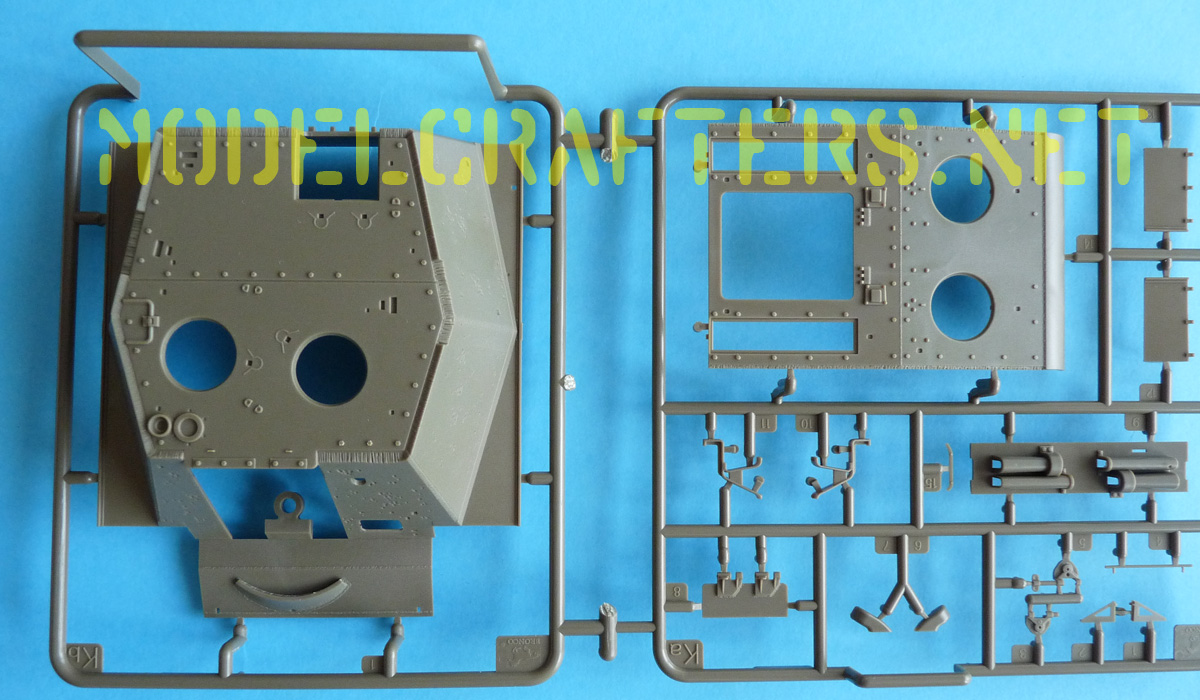

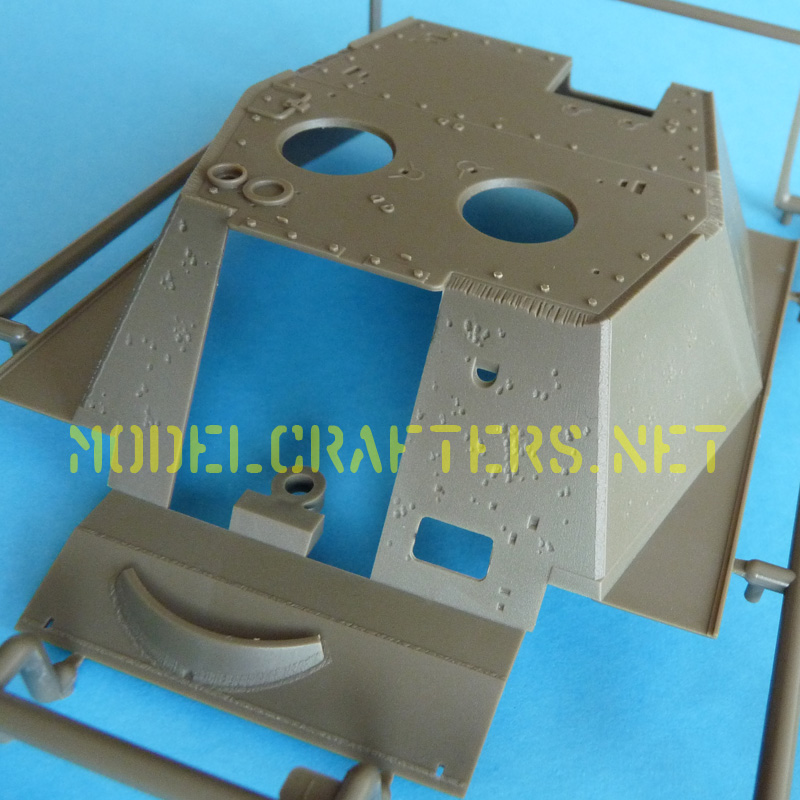

Casemate and engine deck used as per instructions. You can see there are no mesh screen molded on this one as opposed to the deck on Sprue A.

Bronco has erroneously molded detail that makes the superstructure look like it’s cast – which it isn’t. It was welded together from rolled sheets of armored steel, which were surface hardened, so no that big blemishes could exist on them in real life. Well if they sat 50 years out in the open – maybe such defects would appear with time, however…

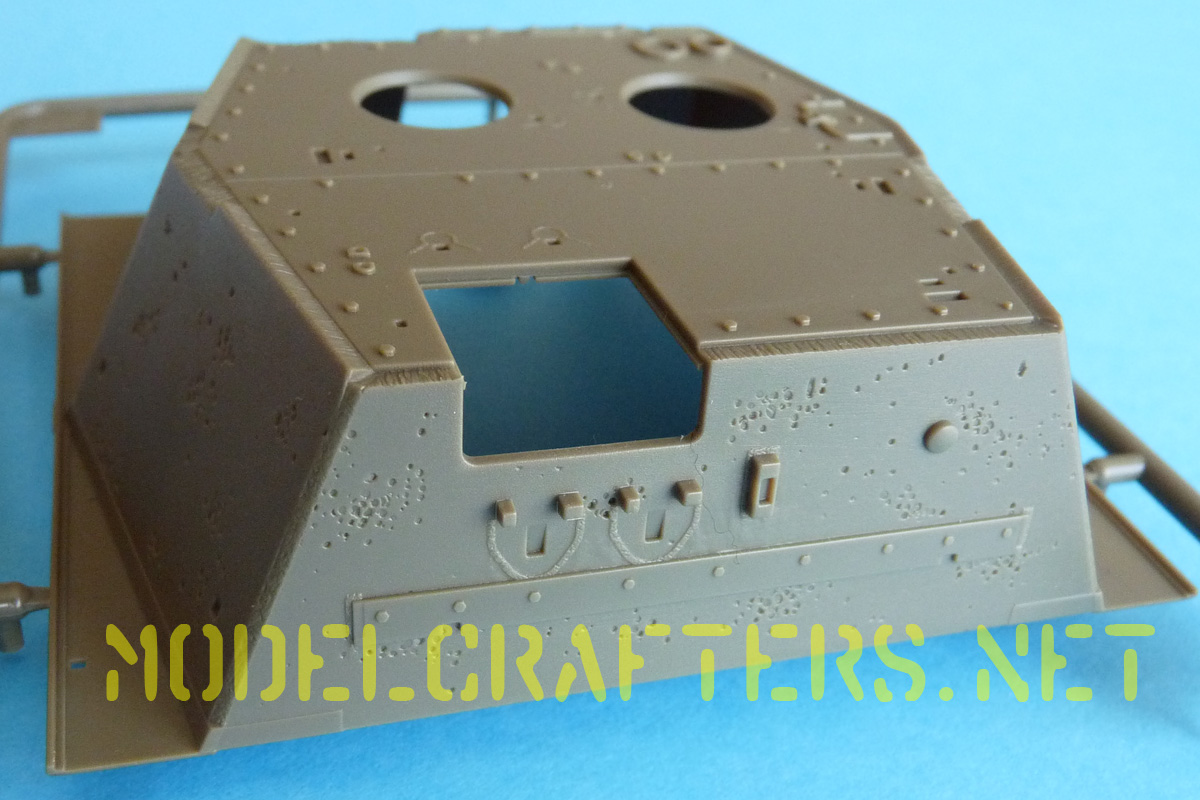

Right side – the only hatch left unopened….

Rear end. You have already noticed the jagged edges of the individual sheets making up the superstructure, simulating the scars left from the gas cutter.

Notice the pistol port plug, and the locating holes for the periscopes and their armored covers.

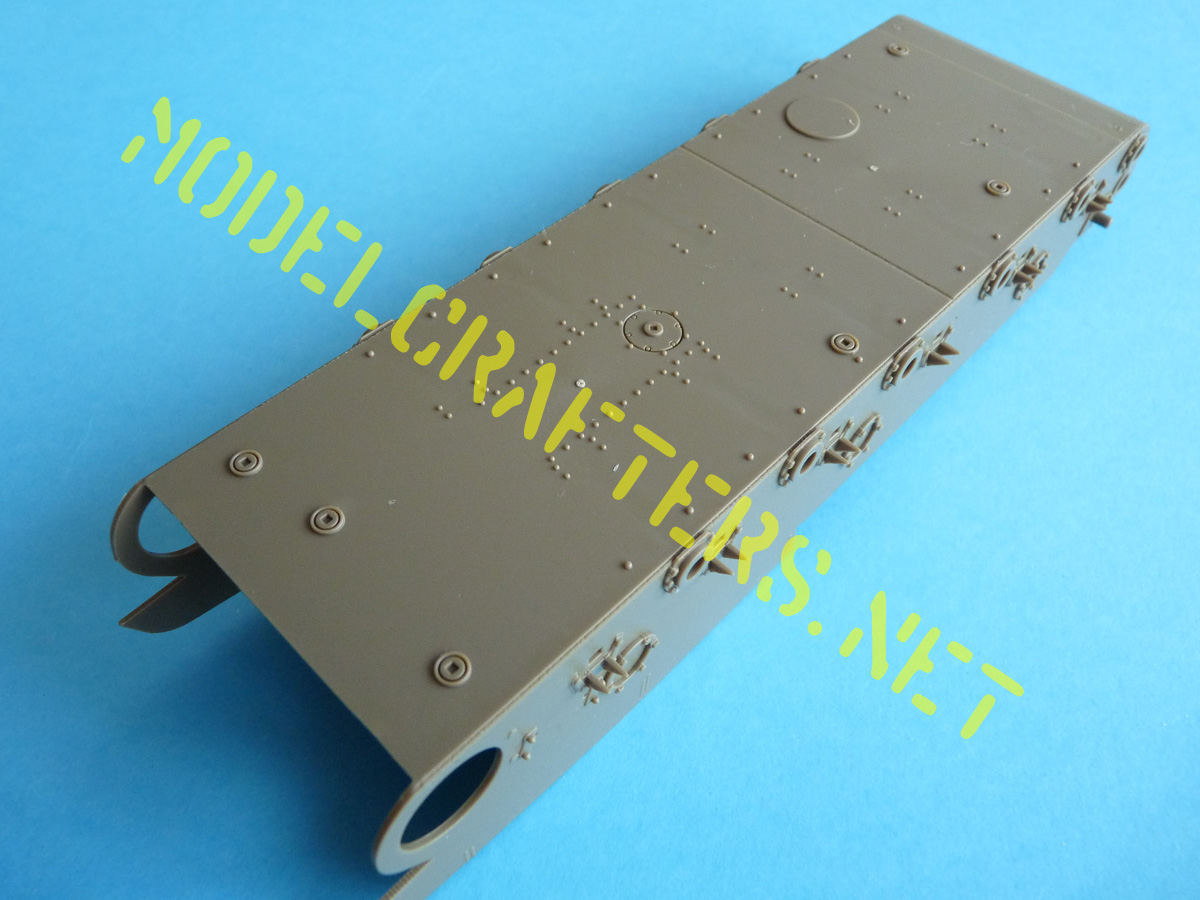

Engine deck displaying raised bolt head details, as well as carefully mastered weld seams.

Slide molded exhausts will save you some work hollowing them out. To the right is a part of a hatchway hinge.

Intake screen frames to support the PE mesh, and optional injected plastic substitutes with molded-in sag.

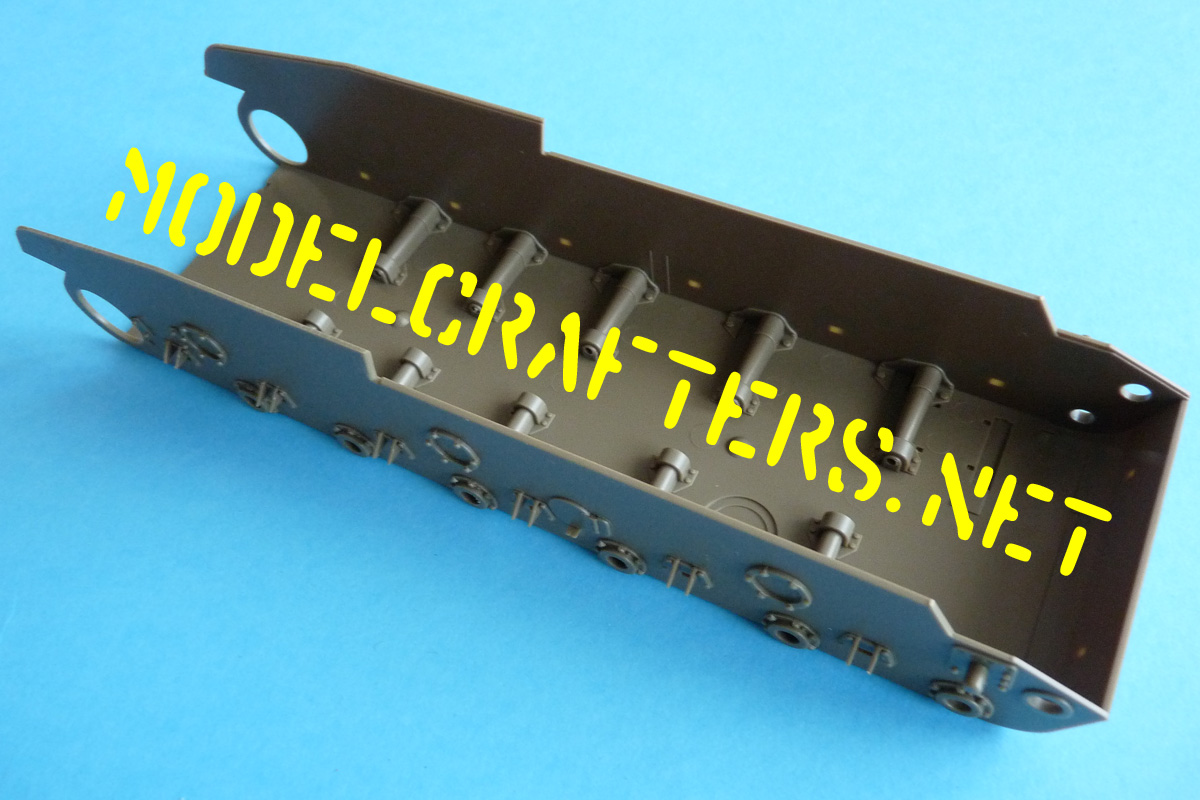

Hull tub with staggered suspension ports.

Hull bottom with escape hatch, oil drains and bolt details for the engine mount.

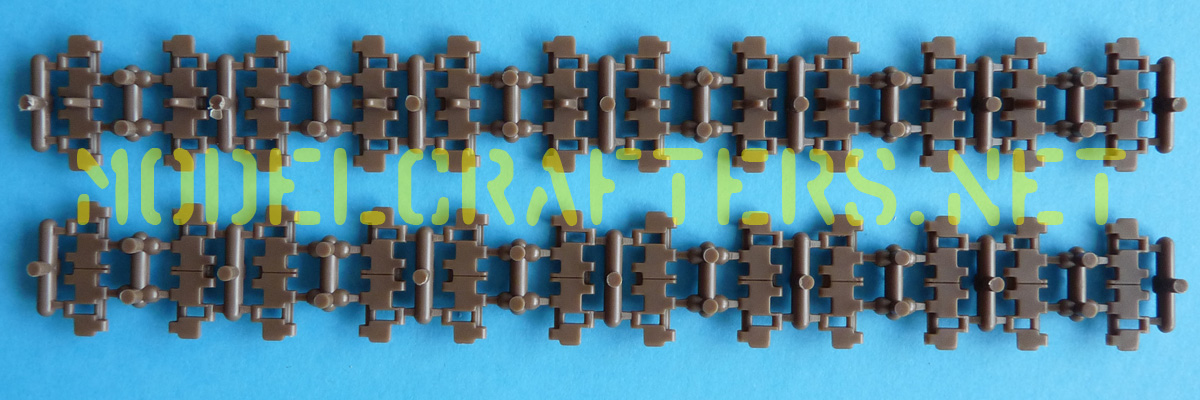

The sprues holding the two track types.

Closer look at the tracks. Note cast structure.

Details on the inside.

Note teethless tracks are of the split type as is correct for the KV-based SPGs of the period.

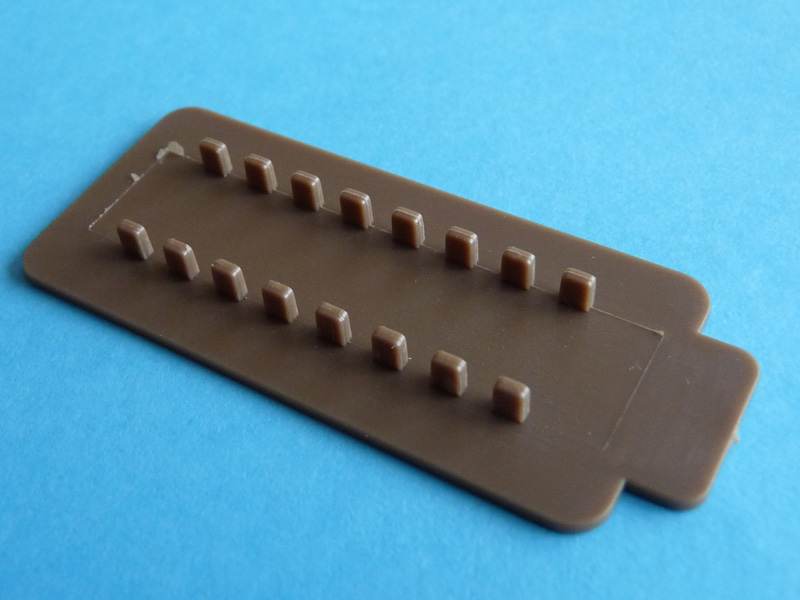

This little guy is the biggest helper in the kit, as it aligns the separate track, helping create sections of 8 tracks to join and make up the complete track run for each side.

Well that’s about it. Next installment shall be of building this beast. From what I see in the sprues this is a great kit, and although the instruction is a big scary in terms of volume – construction steps are logical and easy to follow, pretty far from the crowded (and often misleading) Dragon ones.