The AT-T (Russian “Artilleriyskiy Tyagach – Tyazholiy”, Artillery Tractor – Heavy) was developed in the late 1940s using elements of the T-54 MBT (notably the running gear).

The main purpose of the vehicle was to tow heavy artillery pieces like the KS-30 130mm AA gun, the S-23 180mm gun and the B-4 203mm howitzer, so the machine got a 415HP version of the famous B-2 V-12 tank diesel. The standard 5-roadwheel chassis was used for a number of recovery and engineering vehicles. Extended versions (7 roadwheels) include the P-40 „Long Track” mobile radar, and an entire family of polar expedition vehicles.

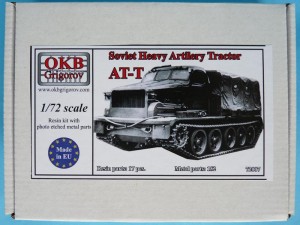

AT-T’s production spanned three decades and ended in 1979. Many vehicles are is still in service with armed forces around the world today – over 60 years after it was accepted by the Soviet Army. Yet OKB Grigorov’s offering is the first kit of the AT-T tractor I am aware of in any scale.

The current kit provides you with the standard artillery tractor with maximum payload of 5 tons and foldable benches for up to 18 soldiers. Equipment includes a 25 ton winch under the cargo bed floor. The AT-T could tow trailers grossing up to 25 tons.

The part count goes up to 253:

83 resin parts

169 photoetched parts on 4 frets

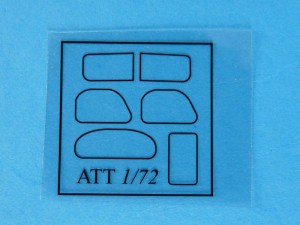

1 clear film with outlines for the cab windows

Resin parts are distributed in 5 zip-lock bags. The PE frets and the film are in a separate bag with cardboard backing. The parts are protected by bubble wrap and a hard cardboard box.

The cabin front features a massive “whale-grin” radiator. The pressurized three-man crew cab is based on the one of the ZiS-150 truck.

The doors and the commander’s roof hatch are separate parts with detail molded on the interior. The outlines of all transparencies are printed on a separate acetate sheet, which I would recommend scanning– just in case.

Two of the windshield windows were hinged on top and could be opened on the real machine, and you can pose them on the model as well thanks to the PE frames and guides supplied.

A single detail represents the engine firewall, cab floor and the seats. There is a separate resin part for the instrument panel.

All the other details inside the cab are represented by PE parts.

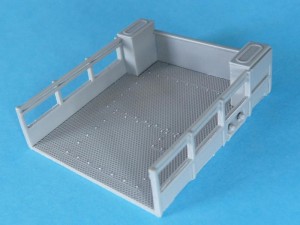

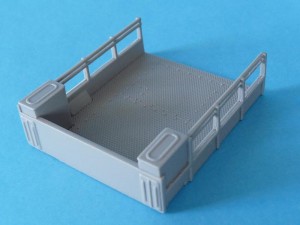

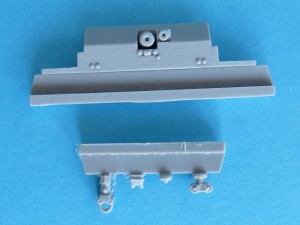

The cargo bed floor (with anti-skid and bolt detail molded on), front and side panels, and the large battery boxes are all a single resin casting.

The back flap and three personnel benches (foldable thanks to the etched hinges) and their supports are all separate details.

Two details comprise the vehicle chassis: a “tub” with integrally molded front bumper, and a back plate to which the towing equipment and the winch port are glued.

This breakdown suggests that OKB Grigorov is considering more vehicles on this chassis that do not have the winch.

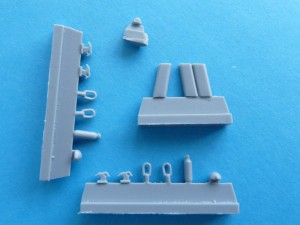

The running gear has the biggest resin part count. The 10 suspension arms are separate items.

This allows you to pose your tractor in an off-road action diorama.

Each wheel is made of two parts that reside on the same casting stub.

The detail on the idlers and roadwheels is excellent, but the rubber bandages on the roadwheels aren’t wide enough. The drive wheels are also made of two resin halves, with the sprockets represented as separate PE parts.

Tracks are provided in 6 equal lengths of resin, and should be bent using hot water.

Detail is adequate and truthfully represents the track pattern. My example still shows the layers typical of the rapid prototyping process – that will hopefully be remedied as production continues.

Last but not least in the resin department are the engine exhaust stubs, tow hooks, fire extinguishers and combat lights.

Overall resin parts are cast with excellent quality, with minor amounts of very thin flash.

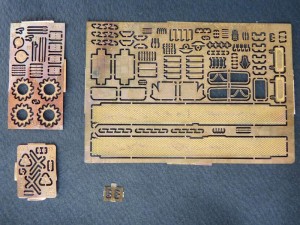

Then there are the photoetched details. The fenders and steps with antislip pattern, all the boxes, hinges, window frames, etc. can be found on two 0,1mm brass sheets.

To better represent the scale thickness of details like the drive sprockets, mud scrapers and ice cleats 36 parts are etched in 0,3mm copper. The quality of PE parts is excellent – detail is crisp and no cleanup is required.

The instructions are printed in color on an A4 sheet, folded to fit in the box. The first page is taken up by the part plan, with the rest of sheet tightly packed with the company’s standard construction diagrams. Paint callouts or schemes are not provided in the instructions.

It turns out the instructions completely miss any reference to the 4 tow cable eyelets in the kit, as well to the tow cable placement, which is really odd if you’re asking me.

Being the first kit of the massive vehicle OKB Grigorov’s AT-T sets a very high standard in terms of both detail and quality. The set will build in an accurate replica of this popular machine.

Highly recommended to experienced modellers.

Many thanks to OKB Grigorov for the review sample.